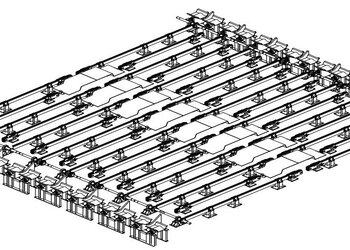

Cooling Bed

| Location | Components |

| At rolling mill exit. |

|

| Dute | |

Step by step bar forwarding and cooling. | |

| |

A- Straightening grids Installed in the first part of the cooling bed to guarantee uniform cooling and bar straightness while the temperature is still in the elastic deformation range. Consisting of a set of cast iron machined and notched elements arranged between the movable rakes of the cooling bed. Complete with supports. | |

B- Fixed and movable frames To support and move the bars forward step by step during the cooling phase between the cooling bed run-in and runout roller tables. Consisting of alternately arranged fixed and movable notched rakes fastened to fabricated steel frames. The rakes are inclined to change the contact point between bar and rake at each step to avoid localized cooling and improve bar straightness. The fixed frame is mounted on foundation columns. The movable frame is mounted on wheels supported by roller bearings, resting on the eccentrics of the transmission shafts.

| |

C- Transmission group For lifting/lowering of the cooling bed movable frame, electrically driven. Consisting of: - Fast transmission between the gearboxes and the motor, including:

- Longitudinal slow transmission including:

The gearboxes are described under a separate item. | |

D- Gear box Worm screw gearboxes installed on the fast transmission line for speed reduction between driving motor and longitudinal shafts for movable frame lifting/lowering. Fabricated steel housing, sealed for oil tightness. Worm screw in NiCrMo steel (casehardened, quenched and tempered), mounted on roller thrust bearings. Gear wheel in bronze mounted on a shaft on roller bearing supports. | |

E- Lining up rollers Installed between the cooling bed rakes for bar alignment on cold cutting side. Consisting of:

| |

F- Aligning stop For bar head aligning on the cold cutting side. Shock absorbing by volute springs. Slightly inclined forwards to prevent bar nose from getting stuck.

| |