The Advantages of EPC Hot Rolling Mills in Steel Industries

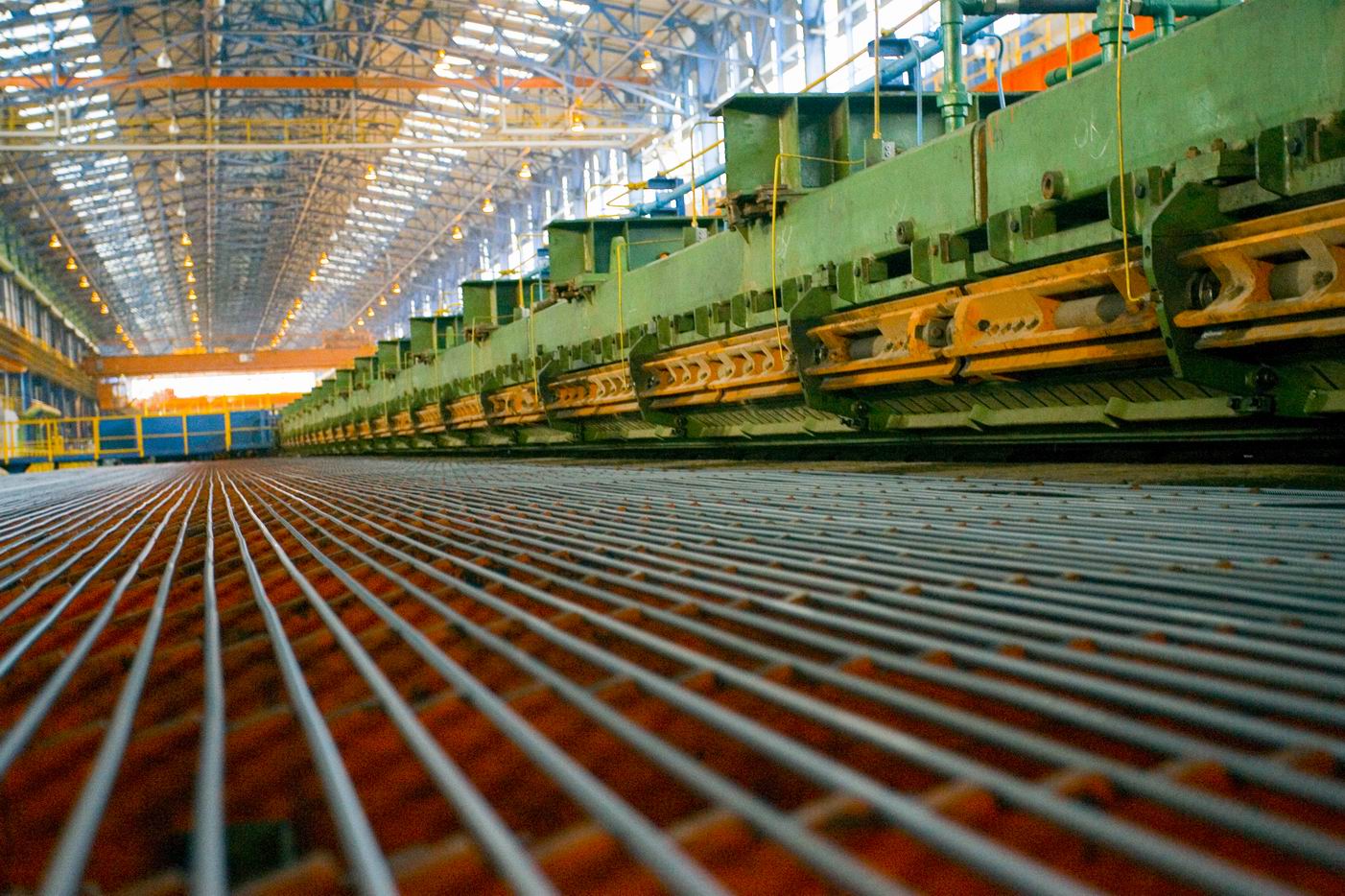

Enhanced Efficiency and Production Capacity: EPC hot rolling mills are designed to optimize efficiency and increase production capacity. Through advanced engineering and cutting-edge technologies, these mills streamline the rolling process, ensuring consistent product quality while minimizing production time. With higher throughput and improved productivity, steel manufacturers can meet growing market demands effectively.

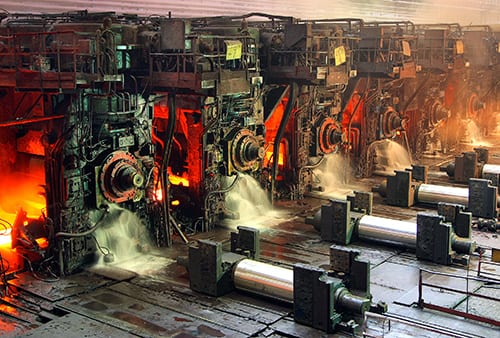

Superior Product Quality: One of the primary advantages of EPC hot rolling mills is the ability to produce steel products of superior quality. These mills are equipped with state-of-the-art automation systems, precision control mechanisms, and advanced monitoring devices. Such features enable precise control over parameters like temperature, pressure, and rolling speed, ensuring uniformity and accuracy in the final product. The result is high-quality steel with excellent dimensional accuracy, surface finish, and mechanical properties.

Flexibility in Product Range: EPC hot rolling mills offer remarkable flexibility, allowing manufacturers to produce a wide range of steel products. Whether it's flat products like sheets and plates or long products like bars and sections, these mills can accommodate various dimensions, thicknesses, and shapes. The ability to adapt quickly to changing market demands enhances the competitiveness of steel companies and expands their product portfolio.

Energy Efficiency and Environmental Sustainability: In recent years, energy efficiency and environmental sustainability have become critical considerations for steel manufacturers. EPC hot rolling mills incorporate innovative technologies that optimize energy consumption and minimize environmental impact. These mills often feature regenerative drives, waste heat recovery systems, and efficient cooling methods. By reducing energy consumption and emissions, EPC mills contribute to a greener and more sustainable steel production process.

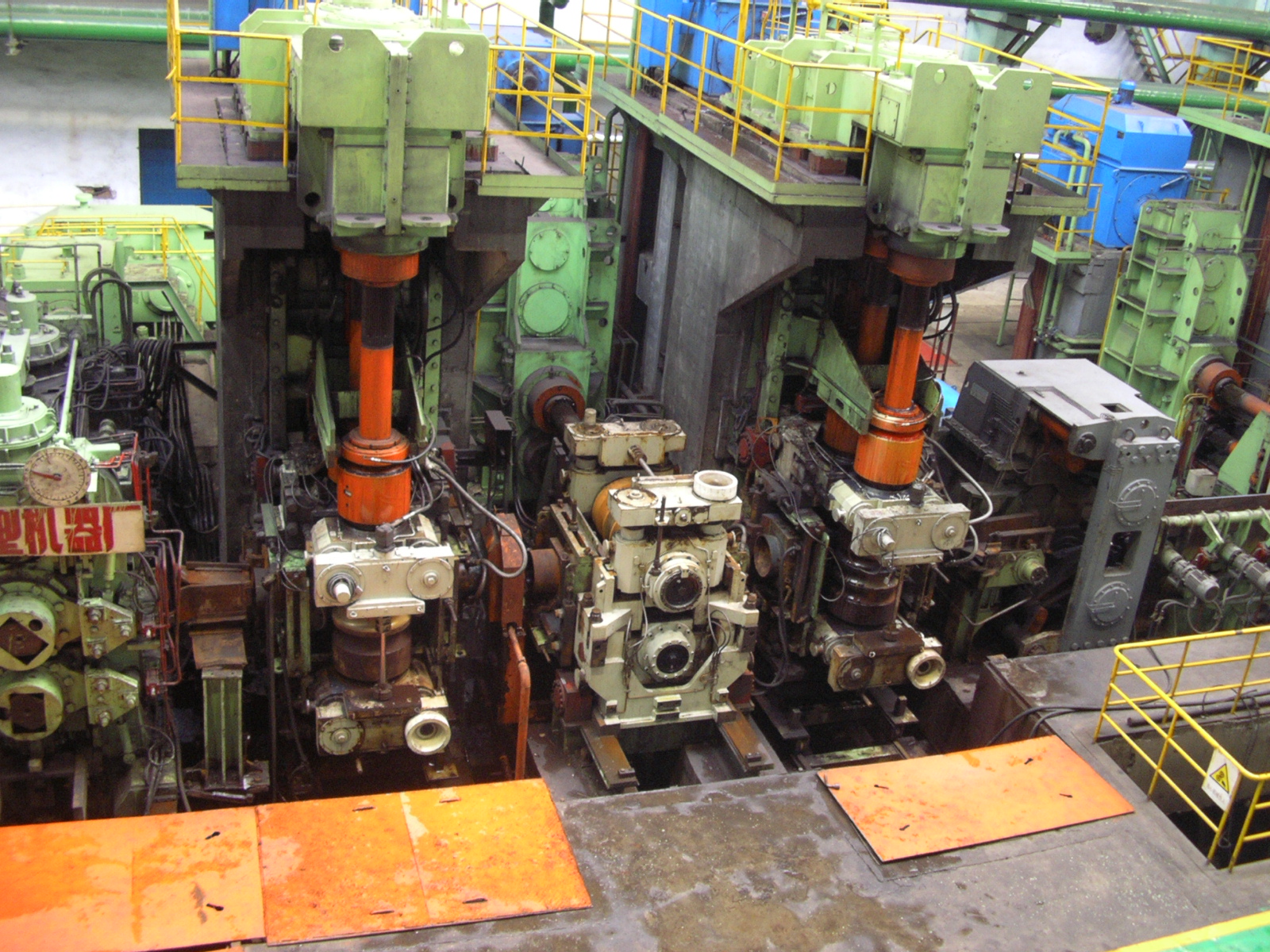

Cost-effectiveness: Efficiency improvements, higher production capacity, and superior product quality achieved with EPC hot rolling mills translate into cost-effectiveness for steel manufacturers. These mills offer reduced operational costs, enhanced yield rates, and minimized material wastage. Additionally, the streamlined process and advanced automation reduce the need for manual intervention, saving labor costs in the long run.

Conclusion: The advantages of EPC hot rolling mills make them a preferred choice for steel manufacturers worldwide. From increased efficiency and production capacity to superior product quality and environmental sustainability, these mills have revolutionized the steel industry. As technology continues to advance, EPC hot rolling mills will play an even more significant role in meeting the ever-growing demands for high-quality steel products.

By investing in EPC hot rolling mills, steel companies can stay competitive, improve their bottom line, and contribute to a sustainable future. As the industry evolves, embracing these advanced technologies will be key to success in the dynamic and demanding steel market.